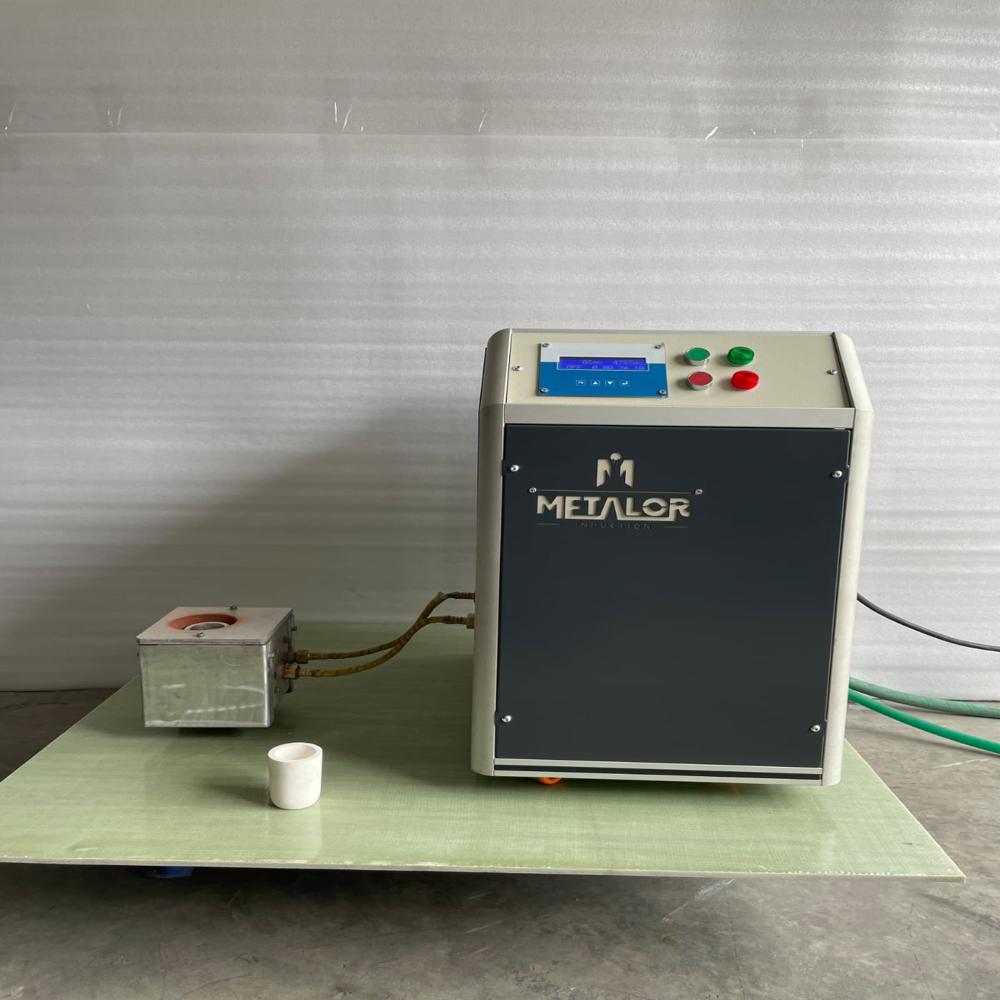

Rhodium Melting Induction Furnace

Price 450000.0 INR/ Unit

MOQ : 1 Unit

Rhodium Melting Induction Furnace Specification

- Feature

- ULTRA ADVANCE MICROCONTRLLER

- Rating

- 25KW

- Usage

- MELTING

- Power

- 30 Horsepower (HP)

- Voltage

- 415V 50Hz Volt (v)

- Product Type

- INDUCTIN

- Color

- Grey / Silver

- Application

- Industrial

- Fuel Type

- ELECTRICITY

- Warranty

- Yes

Rhodium Melting Induction Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 21 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Rhodium Melting Induction Furnace

Other Details:

Advanced Induction Technology

Our Rhodium Melting Induction Furnace utilizes modern induction heating principles, ensuring rapid and uniform melting of rhodium with minimal energy consumption. Its high power capacity (20-30KW) allows for large batch processing while maintaining optimal control and safety within industrial settings.

Reliable Manufacturing and Support

Backed by a comprehensive warranty and manufactured by a reputed supplier in India, this furnace promises longevity and consistent performance. The advanced safeguards and quality assurance processes ensure customers receive a product that meets international standards for industrial use.

FAQs of Rhodium Melting Induction Furnace:

Q: How does the Rhodium Melting Induction Furnace operate for industrial applications?

A: This furnace uses electromagnetic induction to generate heat, efficiently melting rhodium at controlled temperatures. Its 20-30KW power output ensures quick and uniform melting, suitable for various industrial environments where precision and speed are required.Q: What are the main benefits of using this induction furnace for rhodium melting?

A: Key advantages include high-quality build, energy-efficient performance, rapid melting cycles, and consistent output, backed by a reliable warranty. The precise controls help reduce metal loss and improve overall productivity in industrial processes.Q: When is this furnace recommended for use?

A: The furnace is optimal for industrial-scale rhodium melting when efficiency, safety, and consistent results are needed. Its particularly useful in manufacturing facilities, laboratories, and workshops dealing with precious metal processing.Q: Where is the Rhodium Melting Induction Furnace supplied from?

A: This furnace is manufactured and supplied in India by an established and reputable company specializing in industrial melting technologies for precious metals.Q: How is the furnace maintained to ensure long-term usage?

A: Routine maintenance involves checking electrical connections, inspecting the induction coil, cleaning internal chambers, and ensuring proper cooling systems. The products warranty offers support for troubleshooting and repairs, further enhancing longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Induction Melting Furnace Category

Platinum Melting Induction Furnace

Price 45000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Feature : MICROCONTROLLER DUAL IGBT

Application : Industrial

Voltage : 415 Volt (v)

Warranty : Yes

SS MELTING INDUCTION FURNACE

Price 430000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Feature : MICROCONTROLLER

Application : MELTING

Voltage : 415 Volt (v)

Warranty : 1 YEAR AS PER TERM

Gold Melting Induction Furnace

Minimum Order Quantity : 1 Unit

Feature : High Quality

Application : Industrial

Voltage : 230V 50Hz 415V 50Hz Volt (v)

Warranty : Yes

Stainless Steel Melting Induction Furnace

Minimum Order Quantity : 1 Unit

Feature : High Quality

Application : Industrial

Voltage : 415V 50Hz Watt (w)

Warranty : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Call Me Free

Call Me Free